1 / 4

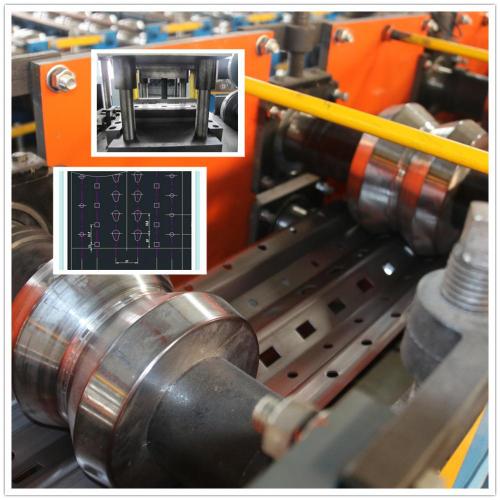

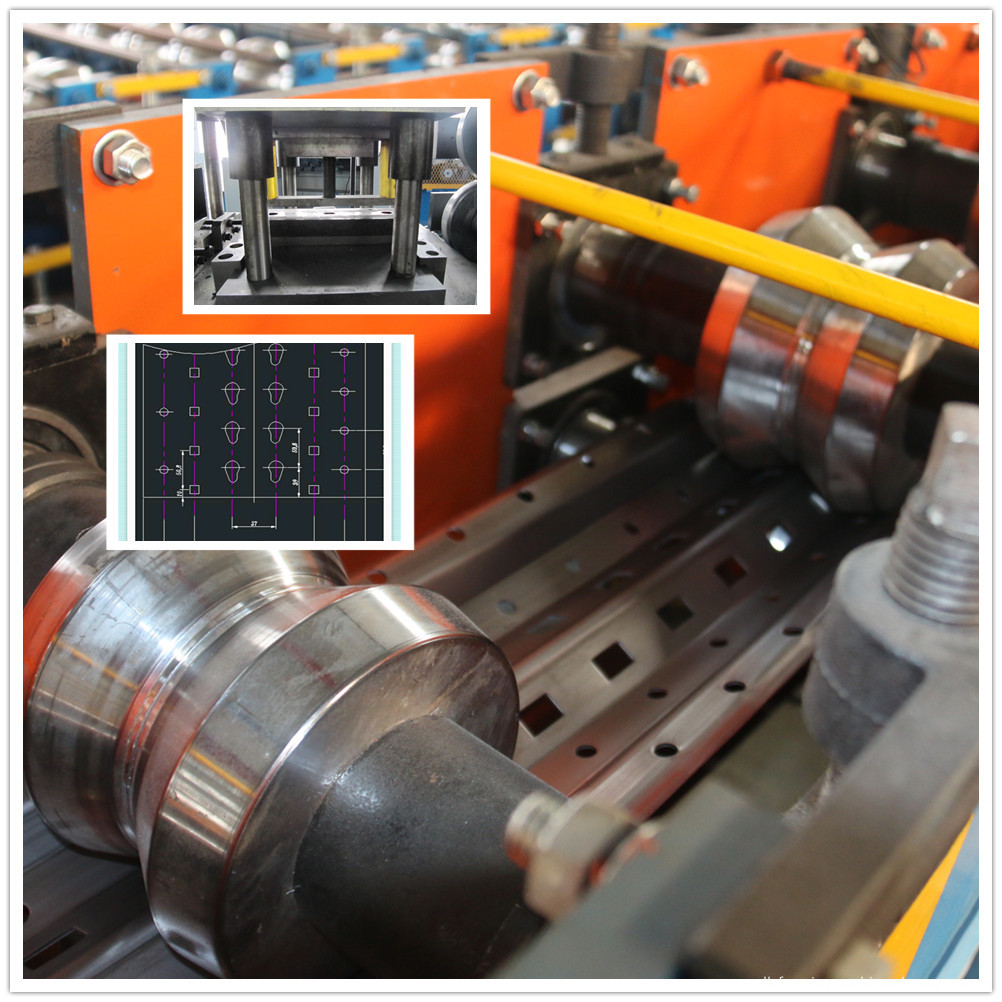

Storage rack upright shelf frame roll forming machine

| Model No. : | CNZT002 |

|---|---|

| Brand Name : | ZHONGTUO |

| Type : | Cold Bending Equal Channel |

Cangzhou, Hebei, China

- nhà chế tạo

- Dịch vụ OEM

- Chứng nhận nền tảng

- Triển lãm trực tuyến

- Băng hình

Mô tả Sản phẩm

Storage rack upright shelf frame roll forming machine

Storage rack upright shelf frame roll forming machine is the machine for making the shelf frame by roll forming principle. Manufactured from customer special drawing profile, this upright pillar simply clip to your existing or new racking without the need for further fixings. Storage racks roll forming machine is adopted for manual access of lighter goods supporter. It can be matched with plastic containers stored more varieties of products, widely used in electronic and small parts warehouse, laying special rubber plate anti-static function by changing the spray or powder. It

has the characteristics of low cost, safety and reliability, simple assembly and disassembly characters. The light warehouse pillar can be used alone and it can also be freely spliced into various permutations.

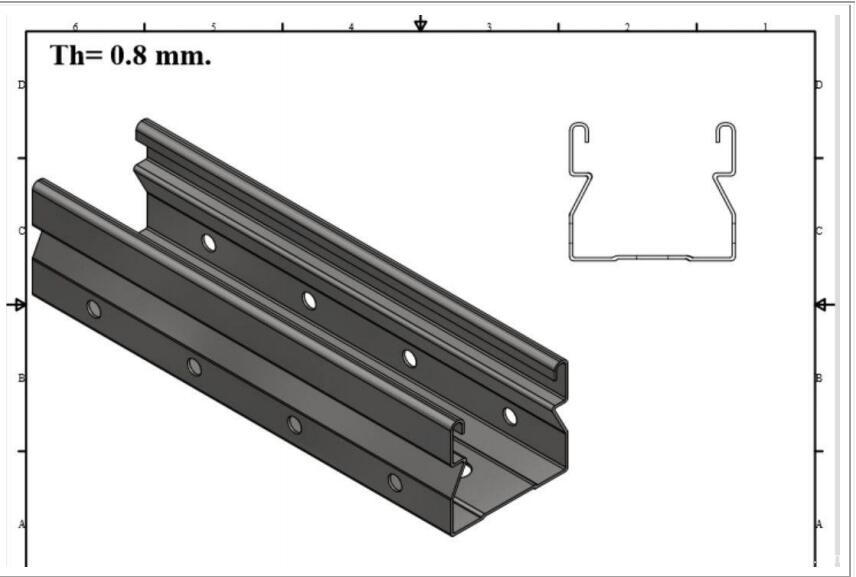

Storage racking roll forming machine is designed to make the up right pillars in batch fully automatically. Here is one of the drawing profiles of light duty upright pillars for your reference:

For the Light Duty upright pillar roll forming machine parameters for your refernece:

Main Roll Forming Machine:

1) Number of rolling stations: 16 rolling stations

2) Shaft diameter: 60mm

3) Shaft material: 45# steel after quenching.

4) Roller material: 45# steel after 62 to 65 degree quenching

5) Transmission method: chain

6) Motor Brand: Chinese famous brand MengNiu

7) Voltage: 380v, 50Hz, 3 phases or customize

8) Machine frame: Middle plate

9) Machine frame thickness: 20mm

10) Main power: 7.5kw

Hydraulic Shearing system:

1).Material: blade and mold material: Cr12 steel with quenched treated 60-62℃

2).Cutting system: advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor.

Control system

1). Screen: Delta screen from Taiwan

2). PLC: Delta DVP14ES from Taiwan

3). Coder: ENC-1-1-1T-24 from South Korea

How to use of upright pillars of light duty:

Storage pallet rack roll forming machine:

Our racking frame roll forming machine has been sent to many countries. Before delivery, we will make seriously testing. After testing you can deliver the machine and the finished upright together by container. By this method, we can confirm that 100% the machine could work smoothly meanwhile the tested finished products will not be wasted.

Company customer show:

Our machines has been sold to more than 40 countries, hoping one day you can join us. With us, creating your own metal world.

Cangzhou, Hebei, China

- nhà chế tạo

- Dịch vụ OEM

- Chứng nhận nền tảng

- Triển lãm trực tuyến

- Băng hình

Gửi yêu cầu của bạn cho nhà cung cấp này